Erro de formato de e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

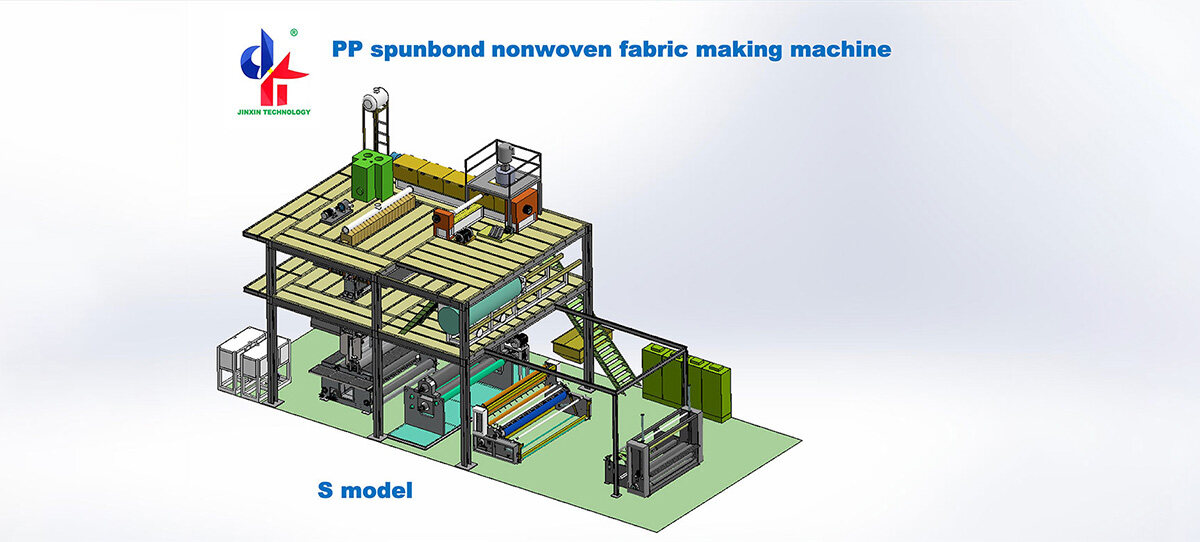

S modelo 3200mm dispositivo de tecido não tecido

A certain amount of moisture is typically present in the polymer chips produced by pelletizing on the conveyor belt; this moisture must be dried and removed before spinning. It is not necessary to dry non-aqueous polymer chips like polypropylene.

| Model | JX-S |

|---|---|

| Product Width | 3200mm |

| Equipment Size | 20*12*12m |

| Mechanical Speed | 150m/min |

| Gram Weight | 10-200g/m2 |

| Daily Output | 9-10T/Day |

| Transformer Capacity | ≈315KVA |

| Power Consumption | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Working Principle Of Spunbond Nonwoven Machine

1.Slicing and baking

The polymer chips obtained by pelletizing on the conveyor belt usually contain a certain amount of moisture, which must be dried and removed before spinning. For non-aqueous polymer chips, such as polypropylene, it is not necessary to dry.

2.Spinning

The spinning equipment and process used in spunbond are the same as those of chemical fiber spinning. The main equipment and accessories are screw extruders and spinneret.

3.Stretch

The newly formed melt-spun fiber (nascent fiber) has low strength, large elongation, and an extremely unstable structure. Therefore, it does not have the properties required for textile processing and must be stretched.

4.Separate wire

The so-called splitting refers to the separation of the stretched two into monofilaments to prevent the fibers from adhering to each other when forming a web

5.Laying the net

The drawn and divided filaments must be evenly laid on the netting curtain. The key to netting is to control the movement of the filament, and its control methods mainly include airflow control and mechanical control.

6.Suck the net

Through the suction net, the downward blowing airflow can be taken away, and the bounce of the tow can be controlled. For this reason, a 20cm-thick vertical diversion air-distributing orifice plate is arranged under the netting curtain to prevent the reverse airflow from blowing over the fiber mesh. A pair of windshield rolls are provided at the suction boundary in the forward direction of the web. The upper roll has a larger diameter and is relatively smooth, and a cleaning knife is set to prevent rolls. The lower roll has a smaller diameter. Rubber rolls are usually used to clamp the web. And into a net curtain. The auxiliary suction duct directly sucks in the air pressure net to control the fiber net to attach to the net curtain.

7.Reinforce

Reinforcement is the last process. Through reinforcement, the fiber web has a certain strength, elongation, and other properties to meet the requirements of the product.

Only if you are familiar with the working principle of the spunbond non-woven machine can you produce a good non-woven fabric. If you want to know more about the spunbond non-woven machine, you can contact us to get more detailed solutions.